The FN MAG58 is a battle-proven general-purpose machine gun that has seen widespread use in various armed forces around the world. The Cuban variant, the FN MAG58 240B, is particularly notable due to its unique history and development.

Overview of the FN MAG58 240B

The FN MAG (Mitrailleuse d’Appui Général) is a Belgian-designed machine gun, utilized for infantry support and vehicle mounting. The MAG58 240B is a specific iteration that was adapted for use by Cuban forces, with slight modifications to suit local operational needs. The weapon is chambered in 7.62×51mm NATO, making it compatible with a variety of ammunition.

Key Features

- Caliber: 7.62×51mm NATO

- Rate of Fire: Approximately 650-1,000 rounds per minute

- Muzzle Velocity: 840 m/s (2,755 ft/s)

- Effective Range: 800 meters (2,625 ft)

- Weight: Around 11.5 kg (25 lbs) without ammunition

Breakdown of the Parts Kit

The FN MAG58 240B kit encompasses a variety of components essential for assembly and maintenance. Understanding each part’s function facilitates better handling, maintenance, and repairs. Below are key components typically included in the parts kit:

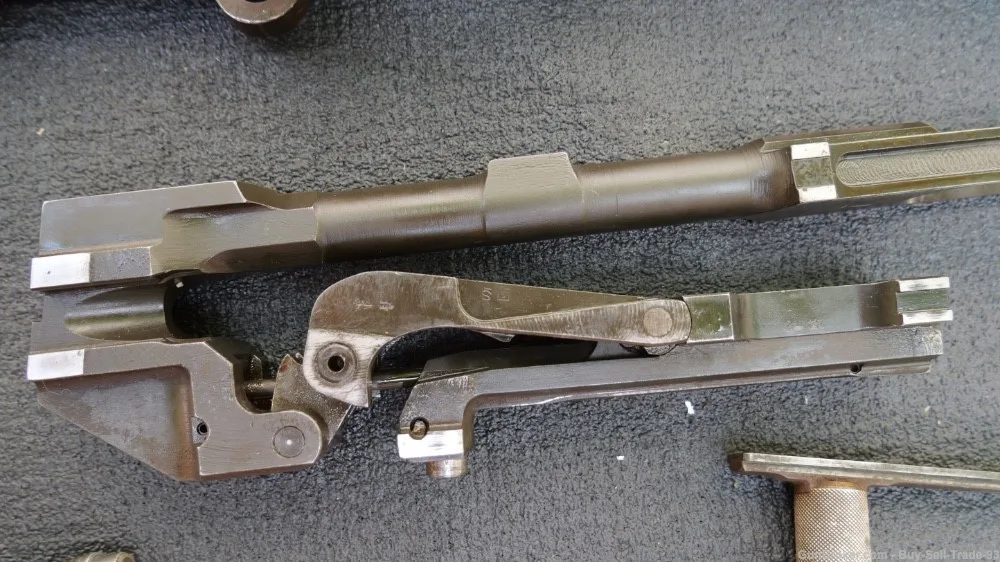

Receiver Assembly

The receiver is the core of the machine gun, housing the firing mechanism and serving as the attachment point for other components. It incorporates the trigger and safety mechanisms, ensuring the gun operates correctly.

Barrel

The barrel is crucial for accuracy and heat dissipation during rapid firing. The FN MAG58 uses a quick-change barrel system, allowing operators to swap out an overheated barrel in the field swiftly.

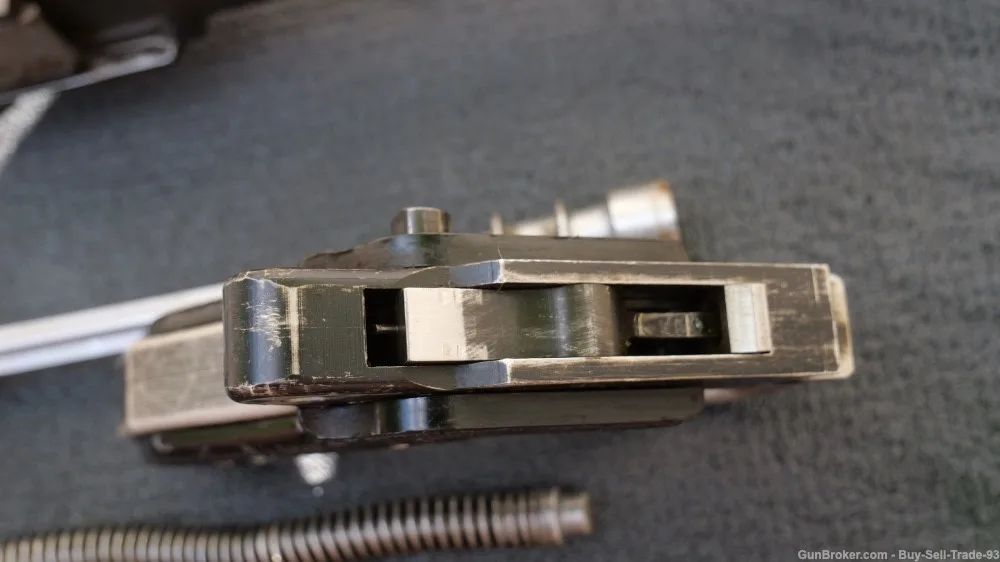

Bolt and Bolt Carrier

The bolt assembly is responsible for chambering the round and initiating the firing sequence. It is paired with the bolt carrier, which facilitates the action of ejecting spent cartridges.

Feed Tray and Belt Holding Pawl

The feed tray guides ammunition into the chamber, while the belt holding pawl ensures that the ammunition belt is secured during firing, preventing jams.

Stock and Handguard

These components provide stability and comfort during firing. The stock helps absorb recoil, while the handguard protects the user from the hot barrel.

3. Tools and Equipment Required

Before you begin assembling your FN MAG58 240B, ensure you have the following tools and equipment on hand:

- Torque Wrench*: To ensure components are securely fastened to specified torque settings.

- Screwdrivers*: A set of Phillips and flathead screwdrivers to accommodate various screws.

- Pliers*: For gripping and manipulating smaller components.

- Gun Cleaning Kit*: Essential for ensuring all parts are free from debris and properly lubricated.

- Safety Glasses*: Always wear protective eyewear during assembly and testing.

Steps for Assembling the FN MAG58 240B Kit

Assembling the FN MAG58 240B kit requires careful attention to detail and adherence to the manufacturer’s instructions. Follow these steps for proper assembly:

Step 1: Inspect All Components

Before assembly, inspect all parts for damage or wear. Ensure that all required parts are included in the kit and free from any defects.

Step 2: Assemble the Receiver

Start by attaching the trigger mechanism within the receiver housing. Secure the safety selector switch and connecting rods, ensuring smooth operation.

Step 3: Attach the Bolt Carrier and Bolt

Insert the bolt into the bolt carrier and insert the assembly into the receiver. Ensure it moves freely when the charging handle is pulled back.

Step 4: Install the Barrel

Align the barrel with the front trunnion of the receiver. Once aligned, lock it in place using the appropriate locking mechanism. This may include rotating the barrel to the locked position.

Step 5: Connect the Feed Tray

Install the feed tray over the receiver, ensuring it clicks into place securely. This component is critical as it will guide the ammunition into the chamber during operation.

Step 6: Secure the Stock and Handguard

Attach the stock to the rear of the receiver, securing it with screws or pins as specified in the assembly instructions. Next, fit the handguard over the barrel assembly. This part often requires rotation and clicking into place to secure it.

Step 7: Conduct Initial Function Check

Perform a basic functions check to ensure that the trigger mechanism operates smoothly, and the bolt cycles correctly. While the gun should not be loaded, ensure that parts move freely and engage as expected.

Step 8: Final Inspection and Lubrication

Inspect the assembled machine gun to ensure that all parts are installed correctly and securely. Apply appropriate lubricant to moving parts as per the manufacturer’s specifications to ensure smooth operation.

Maintenance Tips for Longevity

- Cleaning After Use: After each shooting session, conduct a thorough cleaning. Remove any residue from the barrel, chamber, and bolt using a cleaning rod and solvent. Be sure to clean the feed tray area as well, as dirt accumulation can cause feeding issues.

- Regular Inspections: Periodically inspect the machine gun for signs of wear or damage, particularly focusing on the barrel, bolt, and receiver. Address any issues immediately to prevent further damage or failures.

- Lubrication: Regularly lubricate moving parts, especially the bolt and carrier, impact points, and trigger mechanism. A well-lubricated machine gun operates more efficiently and reduces the incidence of jams.

- Proper Storage: Store the FN MAG58 240B in a controlled environment to protect it from moisture and corrosion. Use a protective case or rust-preventative oil on metal surfaces for added protection.