The Madsen M50 was designed by Danish engineer and artillery officer, R. Madsen, and first introduced in 1950 as a lightweight, versatile firearm intended for both military and police use. Its compact design and ease of use made it effective in urban and close-quarters combat scenarios. The M50 saw service in various conflicts and was produced in limited numbers, leading to its status as a sought-after collectible today. The firearm’s reliability and accuracy have made it a favored choice, contributing to the demand for M50 parts kits among enthusiasts and collectors.

2. Components of the Madsen M50 Parts Kit

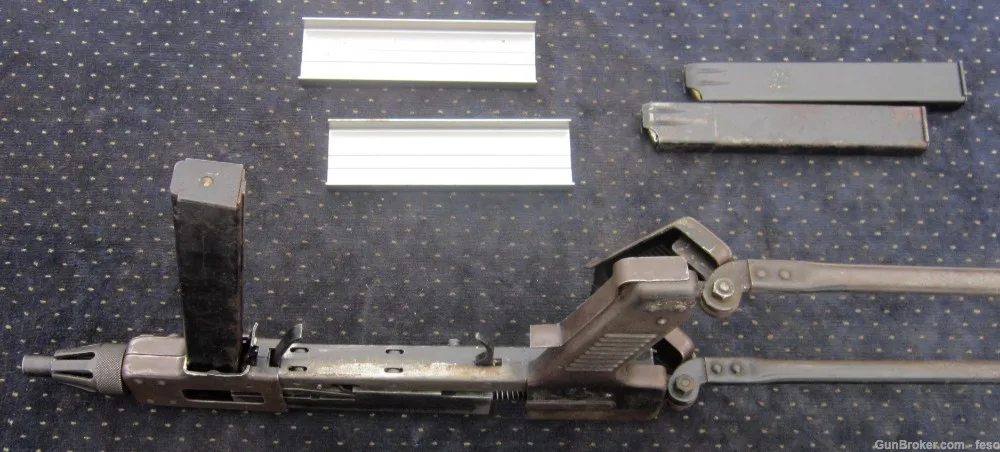

A typical parts kit for the Madsen M50 includes essential components required for the assembly or restoration of the submachine gun. Key elements of the kit typically include:

Receiver: The backbone of the firearm, housing the internal mechanisms.

Barrel: Integral for accuracy and range, usually made from high-quality steel.

Bolt Assembly: Responsible for the blowback operation and firing mechanism.

Stock: Often made of wood or polymer, providing stability and ease of handling.

Trigger Group: Essential for controlling the firing process, allowing for semi-automatic or full-auto firing modes.

Magazine: Typically capable of holding 30 rounds, critical for semi-automatic or automatic firing.

Compatibility and Modifications

When dealing with parts kits, it’s important to verify the compatibility of the components, especially if modifications are being considered. While many Madsen M50s have similar specifications, variations may exist based on the production year and model variant. Enthusiasts often explore modifications to enhance performance, improve ergonomics, or even customize aesthetics. It’s advisable to consult with experts or firearms professionals when undertaking such modifications to maintain safety and legality.

Maintenance and Care

Caring for a Madsen M50, whether it’s assembled from a parts kit or is a factory model, is essential to ensure optimal performance and longevity. Regular maintenance practices include:

Cleaning: Regularly clean the barrel and internal components to prevent corrosion and buildup.

Lubrication: Proper lubrication of moving parts is crucial to avoid malfunctions and increase lifespan.

Inspection: Frequently inspect components for wear and tear, particularly the bolt and trigger assembly.